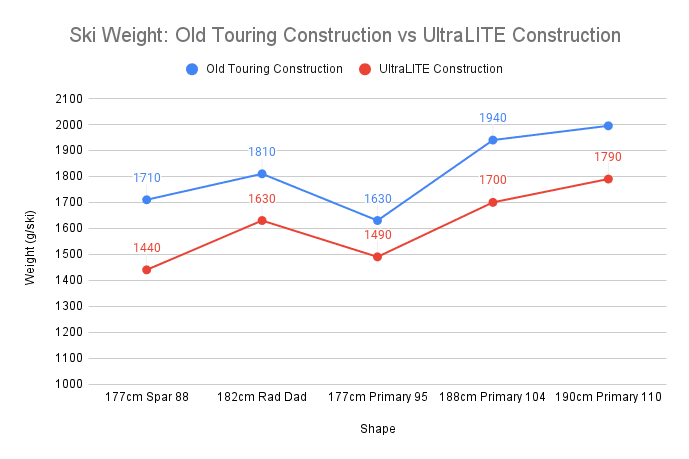

Over the last few years, the shift in the ski industry towards lightweight touring skis has been substantial. Through this time, Folsom’s touring builds have evolved slightly, but even in Folsom’s traditional lightweight touring constructions, skis still weighed in around 1800-2000 g/ski for longer mid-width shapes. This winter and spring, we’ve been prototyping a new touring construction that we’re excited to share with the public. Through the use of lighter materials, and some variation in our core-to-sidewall ratios, Folsom’s new UltraLITE builds are weighing in up to 300 g/ski lighter than before.

Traditional touring skis from Folsom incorporated a vertically laminated Aspen & Bamboo core (8 sheets of Aspen wood split in half by 1 sheet of Bamboo). The cores would vary in thickness and profile based on the ski shape and user’s ski preferences. The builds had full-width UHMW sidewalls, which (combined with the core’s bamboo stringer) kept the skis at a heavier weight. The composite laminate used was a 0/30/60 triaxial carbon fiber weave.

Ski weights using the old touring construction were light in Folsom’s eyes, but relatively heavy compared to other touring-oriented skis on the market. They typically ranged from 1600-2000 g/ski depending on the shape and length.

Moving forward, touring-oriented skis will use Folsom’s UltraLITE construction, ultimately saving up to 300 g/ski over the old construction type. The weight savings here is primarily the result of an optimized core-to-sidewall ratio. Thinner sidewalls and wider, thinner cores allow the core of the ski to be substantially lighter. The core is comprised of vertically laminated Aspen boards, eliminating the heavy bamboo stringer. The composite laminate remains the same 0/30/60 carbon fiber weave as before, but also in an optimized configuration.

In general, lighter skis have a tendency to perform at a lower level. They’re frequently softer, and less powerful, particularly in tricky / variable snow conditions.

Folsom has been able to mitigate performance loss in the lighter weight skis by utilizing an aerospace-grade Functionalized Graphene Oxide additive in the new UltraLITE construction. MITO Materials’ proprietary Functionalized Graphene Oxide is proportionally mixed into the epoxy and hardener during ski layup, and adds a significant level of power and damping to the ski.

A thorough prototyping and R&D process has led to unanimously positive responses by Folsom athletes and staff about the UltraLITE builds. Rather than focusing on weight and performance independently, we wanted to do a deep dive on what we’re calling the “weight-to-performance ratio”. Basically recognizing that the new skis are much lighter than before, but still performing at an appropriate level in a variety of different conditions for the user.

Folsom athlete Jeff Colt said the following about his 182cm Rad Dad UltraLITE prototype, “My overall experience on the UltraLITEs was great. I was really impressed with the weight-to-performance ratio, the handling in variable conditions (more damp than chattery, more nimble than controlling) and even how they laid over on hardpack.”

Doug Mock skis the UltraLITE on a 177cm Spar 88 and said, “Making these skis go uphill is a dream. Having spent over 10 years touring on Folsoms, the evolution is real. My first day on the Ultras, I set skin track straight up the fall line on a 38 degree face. Kick turns are second nature when the pivot-weight is so reduced. On my pack or on my feet, the energy saved compared to my other carbon Folsoms is substantial. Weight-to-performance is in a sweet spot, and I am really pleased by how burly they feel descending.”

Folsom Chief of Operations Max Tabor skis the UltraLITE in a 190cm Primary 110. He commented, “Optimal weight-to-performance ratio. Light enough for efficient uphilling, very solid performance in conditions you ideally access via tour. Cold pow, hot pow, plus both firm and melted out corn were all handled very intuitively by the UltraLITEs.”

You may have noticed all of the UltraLITE prototypes have the same topsheet graphic, incorporating fully contrasting white and black colorways. The debate of what color topsheets hold snow better or worse has been a topic of heavy debate, so we set out to settle this once and for all. Through rigorous touring across the western US from February through May, the darker shades on topsheets proved to hold significantly more snow than the the lighter portions. Of course varying weather and snow density will affect this to some degree, but through our testing, lighter colors on your topsheet graphic will lead to a lighter ski going uphill.

We’re so excited to be offering this construction style to the public. Whether you’re a recreational ski tourer, or spend 100% of your ski days in the backcountry, the new UltraLITE builds will be a game changer for you. Feel free to shoot us an email if you have any questions, and fill out a Custom Fit Form to get started on your new favorite touring skis.